Engineering

Engineering is the the key ingredient to the success of any project, whether designed with wood, light gauge steel, ICF, red iron, or concrete. In today’s design/build environment, engineers of record (“EOR”) typically rely on specialty engineers to provide the design for the desired system based upon the EOR’s design criterion. At Wally Walls, our engineers work with your team’s EOR to design the most cost effective, constructable building envelope. Utilizing Wally Walls’ UltraFrame Panels, Wally’s Crown ICF walls, and the architect/EOR’s specified decking system, Wally’s engineers provide stamped structural drawings for the very best insulated, constructable, or non-combustible, structures attainable. Further, our engineer’s structural shops are utilized in slab-to-slab construction. Wally’s UltraFrame Panels are regularly integrated with Type V combustible designs together with wood decking components, providing a lighter weight, better built, Typ V building.

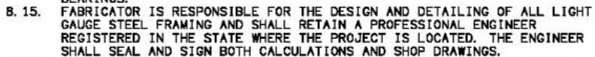

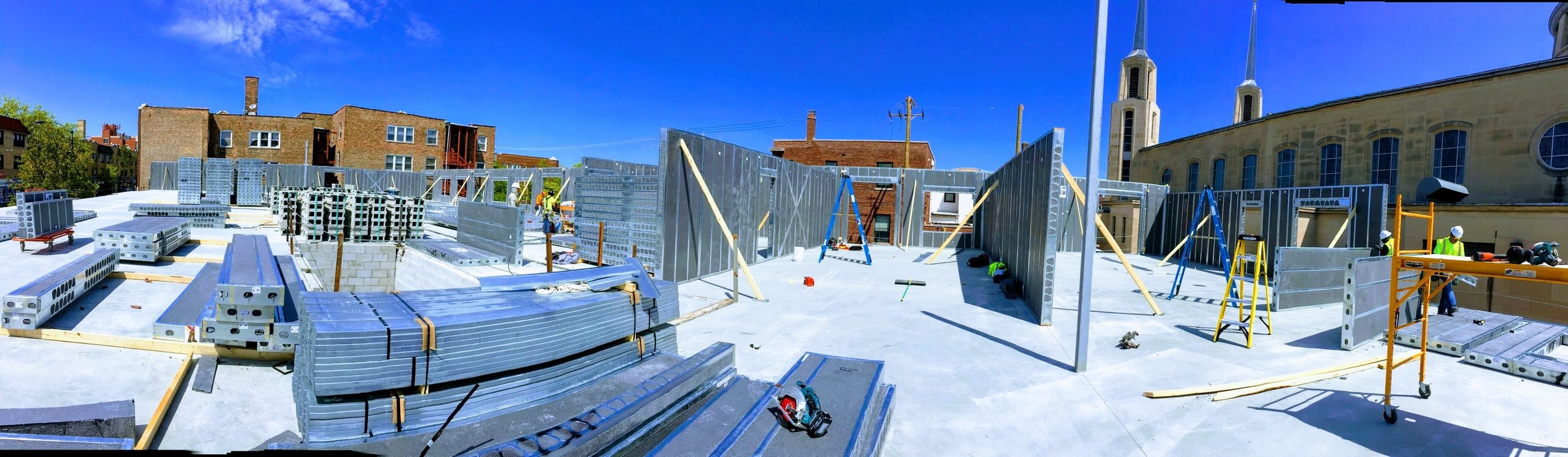

Assembly

Wally Walls UltraFrame Panels go together like a Lego set, handset by Wally’s Installation Team trained to assemble your building. Because the system is so simple, if you already have a pre-selected crew, Wally can work them to assemble the structure. Wally’s Team also handles the Crown ICF installation and decking install. Wally will have you under roof and working inside quickly and without excessive general conditions necessitated with other construction methodologies.

Completing The Envelope

Completing the envelope quickly and efficiently, without drama, and turning the building over to your mechanical trades and framing contractors is our goal. That process starts with our engineering team, moves on to our manufacturing framing crew, and ends with our crew on site, leaving you time to focus on coordinating the mechanical trades, framing carpenters and finishing crews. One contract and Wally does the rest. Simplicity is Better!